Classification Description of Road Studs

Introduction:

Road studs are small devices embedded in the pavement to enhance road visibility and provide guidance for drivers, especially in poor weather conditions or during nighttime. There are various types of road studs available in the market, each with its own unique features, applications, and selection criteria. This classification description focuses on three main types of road studs: Solar Road Studs, Plastic Road Studs, and Aluminum Road Studs.

I. Solar Road Studs:

Solar road studs are equipped with solar panels that capture sunlight during the day and convert it into electrical energy to power-embedded LED lights. The key features of solar road studs are as follows:

1. Self-sustaining: Solar road studs are energy-efficient and eco-friendly as they operate on renewable solar energy, reducing the reliance on traditional power sources.

2. High visibility: Equipped with bright LED lights, solar road studs ensure visibility to drivers, promoting road safety during nighttime or in low-light conditions.

3. Long-lasting durability: Solar road studs are designed to withstand various weather and heavy traffic loads. They are constructed to be impact-resistant and waterproof, ensuring their longevity and functionality.

Applications of Solar Road Studs:

1. Highways: Solar road studs are commonly installed on highways and expressways to provide clear lane markings and guidance to drivers, in dark or poorly lit areas.

2. Urban roads: In dense urban areas, solar road studs are used to improve visibility and delineate lanes, thereby reducing the risk of accidents, particularly at intersections and pedestrian crossings.

3. Parking lots: Solar road studs can be installed in parking lots to parking spaces, driveways, and exits, guiding vehicles safely within the parking area.

4. Airports: Solar road serve as runway lights at airports, ensuring safe navigation for pilots during takeoff and landing.

II. Plastic Road Studs:

Plastic road studs, as the name suggests, are made of durable plastic materials, usually fortified with glass or reflective elements for enhanced visibility. The notable characteristics of plastic road studs are:

1. Cost-effective: Plastic road studs are relatively affordable compared to other types, making them a popular choice in budget-conscious projects.

2. Easy installation: Their lightweight design makes plastic road studs easy to handle and install, reducing labor and installation costs.

3. Reflective properties: Plastic road studs incorporate glass beads or reflective materials, allowing them to reflect light from vehicles' headlights, improving visibility on the road.

Applications of Plastic Road Studs:

1. Residential areas: Plastic road studs are commonly used in residential areas to mark lanes, driveways, and pedestrian crossings, ensuring the safety of residents and pedestrians.

2. Rural roads: In rural areas with limited lighting infrastructure, plastic road studs provide guidance and improve visibility for drivers, reducing the risk of accidents.

3. Temporary road markings: Due to their easy installation and removal, plastic road studs are often used for temporary road markings during construction or event management activities.

III. Aluminum Road Studs:

Aluminum road studs are constructed using high-quality aluminum alloy materials, which offer exceptional durability and visibility. The primary qualities of aluminum road studs are:

1. Exceptional durability: Aluminum road studs are highly resistant to corrosion, impact, and wear, making them suitable for high-traffic roads and harsh weather conditions.

2. Reflective properties: Aluminum road studs feature prismatic reflectors that ensure good light reflection, providing clear guidance to drivers.

3. Longevity: With their robust construction, aluminum road studs have a longer lifespan compared to other types, reducing maintenance and replacement costs over time.

Applications of Aluminum Road Studs:

1. Highways and motorways: Aluminum road studs are widely used on highways and motorways to mark lanes and enhance the visibility of junctions, reducing the risk of accidents.

2. Seaports and industrial areas: Due to their durability, aluminum road studs are commonly used in seaports and industrial areas with heavy machinery and constant traffic, ensuring long-lasting visibility.

3. Curved roads: The exceptional reflective properties of aluminum road studs make them suitable for curved roads, providing clear guidance to drivers in sharp turns and bends.

Selection Considerations for Road Studs:

1. Road conditions: Consider the road type, traffic volume, and environmental factors when selecting road studs to ensure they can withstand the specific conditions of the area.

2. Visibility requirements: Determine the required level of visibility based on the location and purpose of installation, choosing road studs accordingly.

3. Maintenance and durability: Assess the durability and maintenance needs of different road studs to select the cost-effective option for the long term.

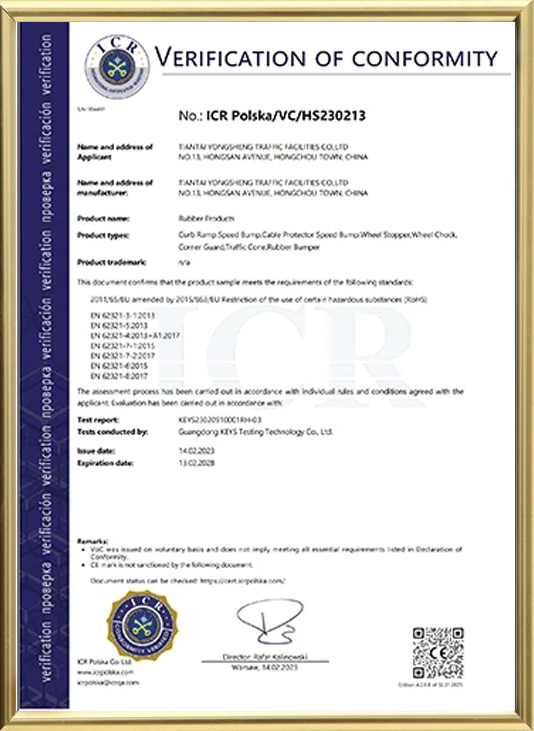

4. Standards and regulations: Ensure the road studs comply with relevant safety standards and regulations established by local authorities or transportation bodies.

In conclusion, road studs play a crucial role in enhancing road visibility and ensuring safety for drivers. The Solar Road Studs, Plastic Road Studs, and Aluminum Road Studs offer distinct features and are suitable for diverse applications. By considering the specific requirements of the road and adhering to selection criteria, appropriate road studs can be chosen to contribute to safer and well-guided roadways.

English

English русский

русский Español

Español عربى

عربى