Enhancing Dock Safety: The Versatility of Laminated Dock Bumpers

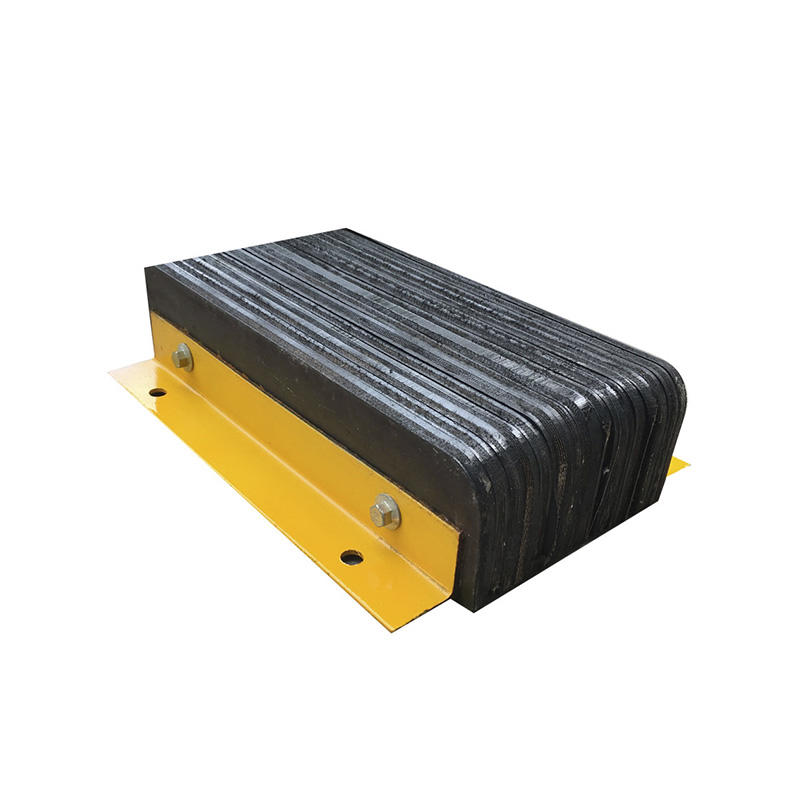

In the realm of loading dock safety, laminated dock bumpers have emerged as essential components for protecting both facilities and vehicles from damage during loading and unloading operations. These bumpers, also known as laminated bumpers or laminated rubber dock bumpers, offer unique advantages in terms of durability, versatility, and impact absorption.

Functionality of Laminated Dock Bumpers:

Laminated dock bumpers are designed to provide superior impact absorption and protection for loading dock equipment and vehicles. They are constructed using multiple layers of rubber or polymer materials, laminated together to form a resilient and durable barrier against impacts. The laminated construction enhances the bumper's ability to absorb shock and distribute impact forces evenly, reducing the risk of damage to both the dock structure and the vehicles being loaded or unloaded.

Versatility in Applications:

The versatility of laminated dock bumpers makes them suitable for a wide range of loading dock applications across various industries. Whether installed on dock walls, loading dock levelers, or dock shelters, these bumpers effectively safeguard critical infrastructure from damage caused by repeated vehicle impacts. Additionally, laminated dock bumpers can be customized to accommodate specific dock configurations, ensuring good fit and performance in different loading environments.

Benefits of Laminated Dock Bumpers:

Enhanced Durability: The laminated construction of these bumpers provides exceptional resilience and durability, allowing them to withstand heavy-duty use and exposure to harsh environmental conditions without deteriorating or losing effectiveness.

Superior Impact Absorption: Laminated dock bumpers excel in absorbing and dissipating impact forces, minimizing the risk of damage to loading dock equipment, vehicles, and structural components, thereby reducing maintenance costs and downtime.

Noise Reduction: The rubber or polymer materials used in laminated dock bumpers help dampen noise and vibration generated during loading and unloading operations, creating a quieter and more comfortable working environment for personnel and nearby occupants.

Easy Installation and Maintenance: Laminated dock bumpers are designed for straightforward installation using mounting hardware or adhesive, requiring minimal time and effort. Routine maintenance involves simple cleaning and inspection to ensure continued performance and longevity.

Applications of Laminated Dock Bumpers:

Loading Dock Walls: Laminated dock bumpers are commonly installed along the walls of loading docks to protect building structures from damage caused by backing vehicles.

Dock Levelers: These bumpers can be mounted on dock levelers to cushion the impact between the leveler and the vehicle, preventing damage to both components.

Dock Shelters and Seals: Laminated dock bumpers are also utilized in dock shelters and seals to provide additional protection against impacts and abrasion during loading and unloading operations.

Customization Options:

Another advantage of laminated dock bumpers is the ability to customize them to suit specific application requirements. Manufacturers offer a range of options in terms of dimensions, thicknesses, and configurations to accommodate various loading dock setups and equipment. Additionally, customization extends to color choices and branding options, allowing businesses to align the appearance of the bumpers with their corporate identity or safety signage schemes. This flexibility in customization ensures that laminated dock bumpers not only provide superior protection but also integrate seamlessly into the overall aesthetics of the loading dock environment.

Environmental Sustainability:

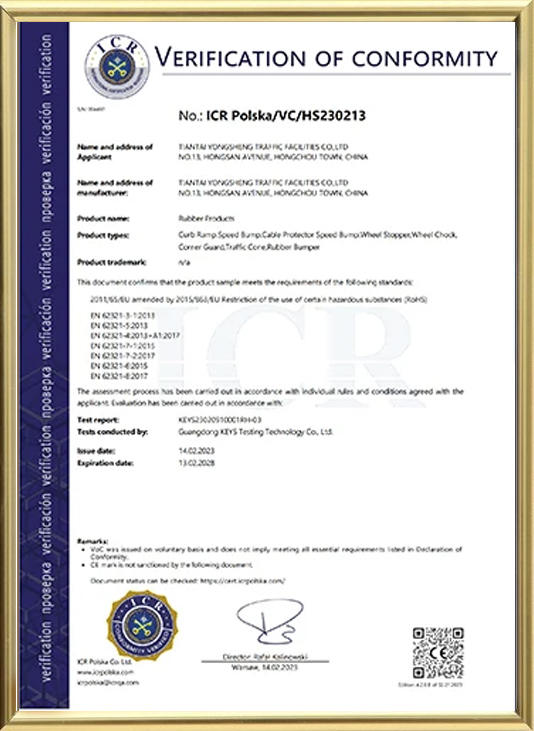

In recent years, there has been a growing emphasis on sustainability in manufacturing practices, and laminated dock bumpers are no exception. Many manufacturers prioritize environmental sustainability by utilizing recycled rubber materials in the production process. By repurposing waste rubber from other industries, laminated dock bumper manufacturers reduce the environmental footprint of their products while still maintaining the high standards of quality and performance. Additionally, the longevity and durability of laminated dock bumpers contribute to extended product lifecycles, further reducing waste generation and promoting resource conservation.

Laminated dock bumpers play a vital role in enhancing loading dock safety and efficiency by providing superior impact absorption and protection against vehicle collisions. Their versatility, durability, and ease of installation make them indispensable components in a wide range of industrial and commercial loading dock applications.

English

English русский

русский Español

Español عربى

عربى